Advantages of Stainless Steel Casting Floor drains

The floor drain is an important connection between the drainage pipe system and the indoor floor. It is a standard fixture throughout every commercial and institutional building. Stainless Steel Casting Floor drains is one of our Stainless Steel Casting products. As an important part of the drainage system in the house, its performance directly affects the quality of indoor air. Very important for the control of odor in the bathroom.

The main Material and characteristics for Floor drains

Mainly cast iron, PVC, zinc alloy, ceramic, cast aluminum, stainless steel, brass, copper alloy, and other materials.

- 1. Engineering plastics: Engineering is widely used, cheap and cheap.

- 2.cast iron: the price is cheap, easy to rust, not beautiful, rust and hang sticky dirt, not easy to clean;

- 3.PVC: cheap, susceptible to deformation due to temperature, scratch resistance and impact is not good, not beautiful;

- 4.zinc alloy: cheap, extremely easy to corrode;

- 5.ceramic: cheap, corrosion-resistant, not resistant to impact;

- 6.cast aluminum: price mid-range, light weight, rough;

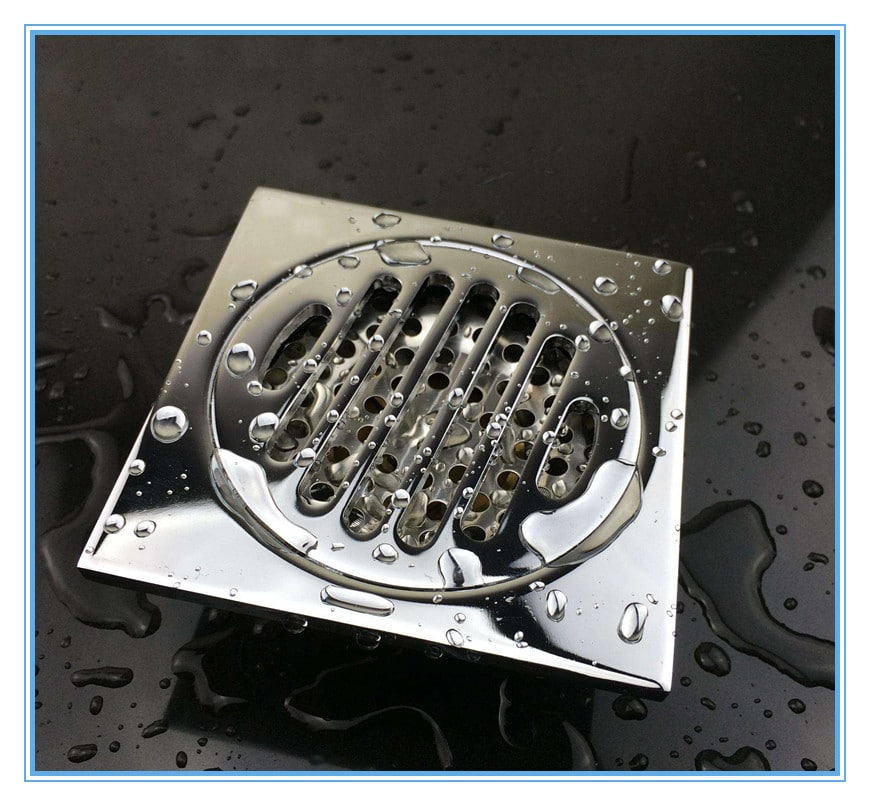

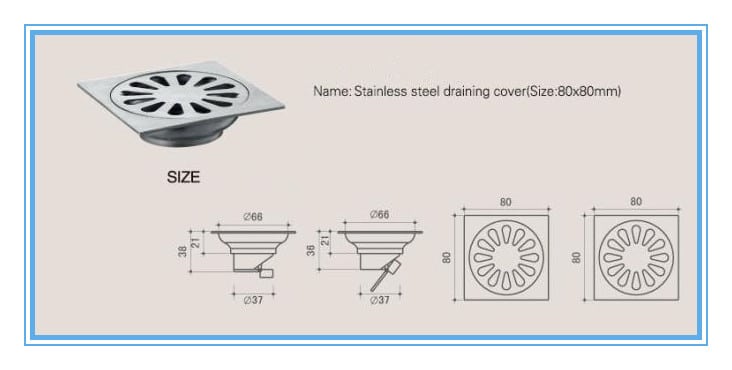

- 7.stainless steel: moderate price, beautiful, durable;

- 8.copper alloy: moderate price, practical.

- 9.brass: heavy, high-grade, high price, the surface can be electroplated.

Stainless Steel Casting for floor drains solution are normally produced in Type CF8 (304). It is an 18-8 Austenitic Stainless Steel with excellent corrosion-resistant qualities. For some applications where conditions demand, Type CF8M (316) stainless steel can be supplied as well. In our Stainless Steel Foundry, both materials 304 and 316 stainless steel can be selected for the floor grain casting. We have the capability to produce different grades of stainless steel castings. After casting, we can polish the cast stainless steel floor grain parts to a smooth finish.

Advantages of Stainless Steel Casting Floor drains

1. Excellent mechanical properties of stainless steel floor drains

The material used has a stainless steel tensile strength greater than 530 N/mm. It is 2 times of galvanized pipe, 3-4 times of copper pipe and 8-10 times of PPR pipe. Has good ductility and toughness.

2.Superior wear resistance

Stainless steel floor drains can withstand high-speed water erosion up to 30 m/s. The stainless steel pipe was used for the diversion of the high water head power station. The water velocity at the end of the nozzle reaches 60 m / sec or more. Still has a service life of more than 100 years.

3.Excellent corrosion resistance

The thin, dense chrome-rich oxide film makes stainless steel water resistant to corrosion, including all waters including soft water. Excellent corrosion resistance even when used in the field.

4.Good temperature resistance

Stainless steel tubes can be safely operated for long periods of time at temperatures from -270 °C to 400 °C. No matter whether it is high temperature or low temperature, no harmful substances will be precipitated. The material properties are quite stable.

5. Environmental protection

Stainless steel is 100% recyclable and is the best choice for casting floor drains.

6. Easy to manufacture.

Thanks to today’s modern steelmaking technology, stainless steel castings can be cut, formed, welded, and machined like traditional steel.

7. The inner wall is smooth and has small water resistance.

Sanitary stainless steel water pipe with a smooth inner wall and very small water resistance. At low flow rates, the water resistance is only 2/5 of that of carbon steel. Reduced pressure loss and reduced transportation costs. Hygienic, not easily stained by bacteria, no fouling.

The faster, more efficient cleaning capabilities of stainless steel make it an ideal choice for harsh sanitary conditions such as hospitals, kitchens, and other food production facilities. Very little maintenance, in most applications, occasional cleaning can restore the surface gloss of the material.

8. Wide Usage

It can be used for hot and cold water projects in home decoration and high-end villa decoration; municipal water supply pipe network, direct drinking water, hot water transportation, medium and high-grade building water supply, hot water pipes for heating, steam pipes, and outdoor high-speed in cold regions. Urban fire water supply, pump room, and other occasions.

9. Long service life.

Comprehensive cost and low corrosion test data show that the service life of stainless steel water pipes can reach 100 years. Little maintenance is required during the life cycle. Avoid the cost and trouble of floor drain replacement. The operating cost is low. the comprehensive use cost (calculated in 50-year service life) is only 1/2 of the cost of the galvanized pipe, 1/4 of the cost of the high-quality PPR pipe, and 1/2 of the cost of the copper pipe.

Ordinary steel castings will rust without rusting. Due to the inherent corrosion resistance of stainless steel, its appearance and finish will have excellent durability. Note: Cast stainless steel will have some surface rust and may be magnetic.

10. Aesthetics

The bright, easy-to-maintain surface of the cast stainless steel floor drains provides a modern and appealing look. Stainless steel finishes are not affected by UV light and do not change color in natural weather conditions.